Is Insulation Foam Board waterproof?

Foam board insulation is a great alternative to the very common fiberglass batt insulation that is in most of our homes. It has a higher R-Value per inch of thickness, it’s resistant to moisture, and is easy to work with.

How Flexibility or Bendability is?

Foam board insulation is a strong but flexible wood that’s unique properties led to its use in sporting equipment and tool handles. Ash has recently increased in popularity as a substitute for Foam board insulation in furniture construction and flooring.

Is it Environmentally friendly?

A manufacturing study showed that the energy required producing polystyrene foam insulation is 24 percent less than the energy required to make the equivalent R-value of fiberglass insulation. EPS is environmentally friendly as it is not manufactured using CFCs or HCFCs- both ozone-depleting chemicals.

What is the Insulation Foam Board thickness range?

Rigid foam insulation products are generally sold as 4 foot by 8-foot sheets (the same size as plywood). They come in several different thicknesses ranging from ½ inch to 2 inches.

Does it come with Panel Shear or Braced Panels Shear?

A shear panel is a strong sheet component that is set inside a casing to expand its capacity to oppose sidelong loads and upsetting minutes. Shear boards work by disseminating horizontal powers starting with one piece of the edge then onto the next or as vertical loads down to the establishments of the structure.

A few shear panels might be associated together in a similar plane to frame a shear wall. These may likewise be solid frameworks that range a few stories or the full stature of the structure. In most business structures, shear walls are huge scope solid structures that are framed from a solitary piece, (for example, a tall shear-wall building). They can likewise be framed from a blend of the board like parts that are unbendingly connected together, (for example, in a distribution center).

‘Insulation Foam Board’

Foam board insulation is a great alternative to the very common fiberglass batt insulation that is in most of our homes. It has a higher R-Value per inch of thickness, it’s resistant to moisture and is easy to work with.

Click here for an explanation of the terms.

This page contains affiliate links.

879other Insulation Foam Board lovers were also interested in this Wood in the last 30 days

Quick Look:

How Insulation Foam Board durability last?

Due to its firmness and water resistance, rigid foam insulation will generally last 100 years or more. The correct installation is essential to take advantage of the durability this product offers.

Where do Insulation Foam Board Sources come from?

The most common types of materials used for loose-fill insulation include cellulose, fiberglass, and mineral (rock or slag) wool. All of these materials are produced using recycled waste materials. Cellulose is primarily made from recycled newsprint. Most fiberglass products contain 40% to 60% recycled glass.

Is Insulation Foam Board Strength?

Sizes and Thermal Properties: Celfort and Foamular high-density insulation boards are available in a variety of thicknesses and standard sizes. Compressive strengths† from 30 psi to 100 psi (210 kPa to 690 kPa) to meet the requirements of nearly every application.

Is Insulation Foam Board Fire Resistance?

All development materials, including froth plastics materials, for example, polyiso protection, should give an appropriate edge of fire wellbeing. Among all froth plastics, polyiso has the most elevated level of inalienable imperviousness to fire because of its special structure of solid isocyanurate synthetic securities.

Insulation Foam Board Unlimited Buyer Guide

What Size Available For Insulation Foam Board On The Market?

Foam board insulation is anything but difficult to utilize and is an extraordinary DIY approach to add some protection. It comes in standard-size 4×8 sheets, and more modest sizes, in various thicknesses from 1/4 inch to 2 inches. A few sorts of thicker froth board protection are accessible, yet they may be exceptionally arranged

Can I Paint, Stain, Glass over Insulation Foam Board?

Just water-based acrylic or latex paint ought to be utilized on froth protection, regardless of whether you are utilizing the material for makes or are painting incomplete dividers. In spite of the fact that froth protected dividers don’t need sanding, they can be sanded, as long as the froth has dried totally first.

What Are Common Types of Insulation Foam Board?

Types of Insulation

| Type | Material | Where Applicable | Installation Methods | Advantages |

|---|---|---|---|---|

| Blanket: batts and rolls | Fiberglass Mineral (rock or slag) wood plastic fibers Natural fibers | Unfinished walls, including foundation walls Floors and ceilings | Fitted between studs, joists, and beams. | Do-it-yourself.Suited for standard stud and joist spacing that is relatively free from obstructions. Relatively inexpensive. |

| Concrete block insulation and insulating concrete blocks | Foam board, to be placed on outside of wall (usually new construction) or inside of wall (existing homes):Some manufacturers incorporate foam beads or air into the concrete mix to increase R-values | Unfinished walls, including foundation walls New construction or major renovations Walls (insulating concrete blocks) | Require specialized skills Insulating concrete blocks are sometimes stacked without mortar (dry-stacked) and surface bonded. | Insulating cores increases wall R-value. Insulating outside of concrete block wall places mass inside conditioned space, which can moderate indoor temperatures. Auto clave aerated concrete and autoclaved cellular concrete masonry units have 10 times the insulating value of conventional concrete. |

| Foam board or rigid foam | Polystyrene Polyisocyanurate Polyurethane | Unfinished walls, including foundation walls Floors and ceilings Unvented low-slope roofs | Interior applications: must be covered with 1/2-inch gypsum board or other building-code approved material for fire safety.Exterior applications: must be covered with weatherproof facing. | High insulating value for relatively little thickness.Can block thermal short circuits when installed continuously over frames or joists. |

| Insulating concrete forms (ICFs) | Foam boards or foam blocks | Unfinished walls, including foundation walls for new construction | Installed as part of the building structure. | Insulation is literally built into the home’s walls, creating high thermal resistance. |

| Loose-fill and blown-in | Cellulose Fiberglass Mineral (rock or slag) wool | Enclosed existing wall or open new wall cavities Unfinished attic floors Other hard-to-reach places | Blown into place using special equipment, sometimes poured in. | Good for adding insulation to existing finished areas, irregularly shaped areas, and around obstructions. |

| Reflective system | Foil-faced kraft paper, plastic film, polyethylene bubbles, or cardboard | Unfinished walls, ceilings, and floors | Foils, films, or papers fitted between wood-frame studs, joists, rafters, and beams. | Do-it-yourself.Suitable for framing at standard spacing.Bubble-form suitable if framing is irregular or if obstructions are present.Most effective at preventing downward heat flow, effectiveness depends on spacing. |

| Rigid fibrous or fiber insulation | Fiberglass Mineral (rock or slag) wool | Ducts in unconditioned spaces Other places requiring insulation that can withstand high temperatures | HVAC contractors fabricate the insulation into ducts either at their shops or at the job sites. | Can withstand high temperatures. |

| Sprayed foam and foamed-in-place | Cementitious Phenolic Polyisocyanurate Polyurethane | Enclosed existing wall Open new wall cavities Unfinished attic floors | Applied using small spray containers or in larger quantities as a pressure sprayed (foamed-in-place) product. | Good for adding insulation to existing finished areas, irregularly shaped areas, and around obstructions. |

| Structural insulated panels (SIPs) | Foam board or liquid foam insulation core Straw core insulation | Unfinished walls, ceilings, floors, and roofs for new construction | Construction workers fit SIPs together to form walls and roof of a house. | SIP-built houses provide superior and uniform insulation compared to more traditional construction methods; they also take less time to build. |

From Where You Can Buy Insulation Foam Board?

| Industrial Enterprises (Pvt) Ltd | Tharmopore Eps/Xps/Polyethylene Roll(Insulation Experts Pakistan) | KRB Enterprises |

| Diamond Jumbolon Store (MWL) | Anees Sikandar & Company |

What Grades Available For Insulation Foam Board On The Market?

| Thickness (inches) | R-Value | Cost (cents/sq. ft.) |

|---|---|---|

| 3 1/2 | 11 | 12-16 |

| 3 5/8 | 13 | 15-20 |

| 3 1/2 (high density) | 15 | 34-40 |

| 6 to 6 1/4 | 19 | 27-34 |

| 5 1/4 (high density) | 21 | 33-39 |

| 8 to 8 1/2 | 25 | 37-45 |

| 8 (high density) | 30 | 45-49 |

| 9 1/2 (standard) | 30 | 39-43 |

| 12 | 38 | 55-60 |

What Is The Best Paint Type for Insulation Foam Board Cabinets?

Only water-based acrylic or latex paint should be used on foam insulation, whether you are using the material for crafts or are painting unfinished walls. … Though foam–insulated walls do not require sanding, they can be sanded, as long as the foam has dried completely first.

What Are Insulation Foam Board Uses?

Typical uses include Exterior consistent protection: Rigid froth can be utilized as sheathing—a persistent layer of protection on wall outsides connected before the establishment of house wrap and siding. Storm cellars: Indoors, unbending froth is the material of decision on dividers where the protection will be contacting stonework.

What Is The Best Brand For Insulation Foam Board?

Best Foam Board Insulation Manufacturers

1: Rmax has been creating insulation based on the latest building science for more than 35 years. The company makes insulation materials for commercial, residential, and specialty projects.

2: Cellofoam has been in the insulation game since 1966. They provide expanded polystyrene foam boards as insulation for residential and commercial buildings, fabricated packaging, marine flotation, and void material.

What Is The Average Cost For Buying an Insulation Foam Board cabinet?

Spray foam is available in two types: open-cell spray foam which usually costs $0.44 to $0.65 per board foot and closed-cell spray foam which averages $1 to $1.50 per board foot. The average total cost to have spray foam professionally installed is about $2,425, or between $1,280 and $3,686.

Home Depot Vs Houzz Vs Amazon

| Market / Size | 1 in. x 2 ft. x 2 ft | 1 in. x 4 ft. x 8 ft | 2 in. x 48 in. x 8 ft |

|---|---|---|---|

| HomeDepot | $5.98 | $19.55 | $34.94 |

| Lowes | $9.95 | $12.48 | $18.88 |

| Amazon | $14.99 | $39.99 | $42.76 |

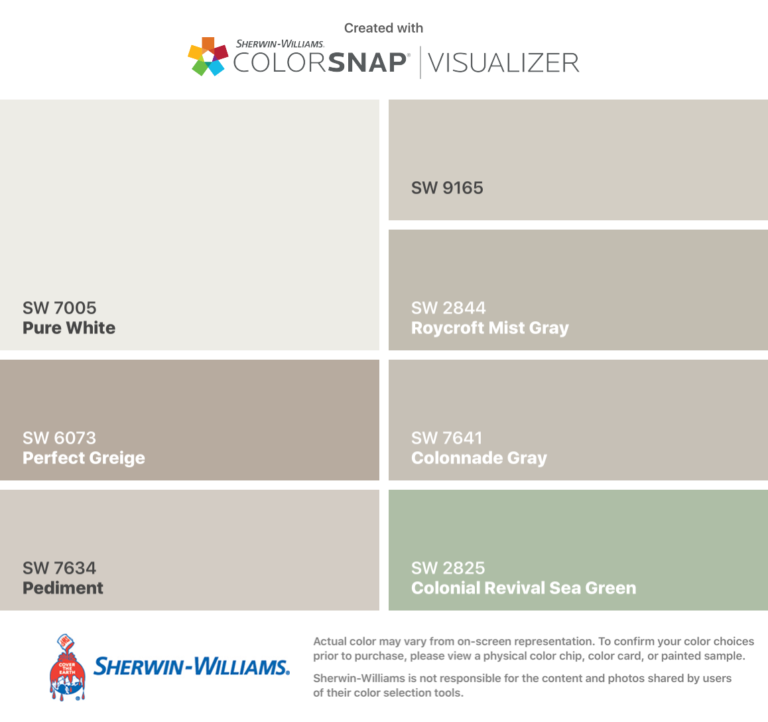

What Are Popular Matching Colors For Flooring With Insulation Foam Board Cabinets?

For cabinets in orangish Insulation Foam Board, a strong complementary flooring option is bluish slate gray. Brazilian slate flooring in green-gray provides an aged, earthen look that links with the rustic flair of Insulation Foam Board Cabinets. Warm-gray flooring coordinates; the neutral gray tone offsets the glowing warmth of Insulation Foam Board Cabinets.

What Are Popular Matching Colors For Walls With Insulation Foam Board Cabinets?

A light colour on Insulation Foam Board Cabinets tends to provide the space with an immaculate and open feel while darker hues give it a more dramatic look. In case your kitchen has one or more walls with red texture or exposed bricks, then white, off-white or some lighter cabinets would create a beautiful contrast.

What Are Popular Matching Colors For Backsplash With Insulation Foam Board Cabinets?

A popular backsplash to pair with Insulation Foam Board Cabinets is the white subway tile. This duo is both classic and trendy, making it a timeless yet stylish pairing. The crisp, clean look of white subway tiles against the playful yet sophisticated blue makes for a modern, contemporary color palette.

What Are Popular Matching Colors For Hardware With Insulation Foam Board Cabinets?

Crupi recommends an oil-rubbed bronze finish that gives “a little less contrast and more of a ‘furniture look’ than a ‘kitchen cabinet look. ‘” Long bar pulls in stainless steel on Shaker-style cabinetry offer clean lines that keep this contemporary kitchen clutter-free

Insulation Foam Board Kitchen Cabinets Ideas & Photos

Final Thoughts:

In this article, you will find all information about Insulation Foam Board, the origin of this wood, the quality of wood, what type of colors are available in the market. From where you get this wood at what price. In this article, you will find all information about Insulation Foam Board.

Wood Strengths Type Guide

- Basswood

- Cherry

- Playwood

- Douglas Fir Wood

- Insulation Foam Board

- Loblolly Pine

- Westem Hemlock

- Solid Wood

- Hardwood

- Softwood

- Particleboard

- MDF

- HDF

- OSB

- Maple

- Oak

- Alder

- Hickory

- Brich

- Walnut

- Pecan

- Sapele

- Ponderosa Pine

- Mahogany

- Butternut

- Ash

- Padauk

- Purpleheart

- Teak

Rot Resistance: Basswood is evaluated as being non-strong as to heartwood rot. Usefulness: Easy to work, being exceptionally delicate and light. Maybe quite possibly the most reasonable wood species for hand cutting. Basswood likewise pastes and completes well, however has helpless steam bowing and nail holding attributes.

Cherry hardwood is a tolerably durable wood; its heart is extremely impervious to spoil and rot. Strength: Cherry hardwood is additionally decently solid and has a medium capacity to oppose stun loads. Adaptability: It is anything but difficult to cut, cut and shape, and is utilized for various applications because of its adaptability.

In contrast to strong wood, plywood gloats of uniform strength along grains paying little mind to bear. This, alongside the utilization of good facade and glues, makes pressed wood truly adept at opposing sharp blows and a wide range of in-administration misuse. That makes it a truly strong item designed wood item.

Douglas Fir is a kind of softwood species that remains dimensionally stable without needing any drying or other treatment. As it is, despite the fact that it is fitted for retaining water, this highly severe environmental dampness of the board property renders this wood waterproof.

Due to its firmness and water resistance, rigid foam insulation will generally last 100 years or more. The correct installation is essential to take advantage of the durability this product offers.

Rot Resistance: The heartwood is rated as moderate to low decay resistance. Workability: Overall, Loblolly Pine works fairly well with most tools, and it glues and finishes well.

Western hemlock has a generally decent solidarity to-weight proportion and is known for its working properties. The wood requires exceptional consideration while drying yet yields a quality item. Its even thickness accommodates brilliant machining properties. It turns, planes and shapes well and can be sanded to a smooth completion.

Solid Wood has durability and strength strong wood furniture goes on for quite a long time, subsequently can be passed down from age to age. Wood tones change from light to dull earthy colored and even red relying upon the assortment of wood utilized.

There are five unique classes of hardwood, as characterized by TRADA, The Timber Research, and Development Association, going from class five to class one, where class five is considered not sturdy and class one is viewed as entirely strong.

Softwood usually lasts about 20 years without any rot, division, or twist. White oak and teak are among the other water-resistant wood types. These are also reliable forests that are impervious to distorting, rotting, cracking, or turning.

According to a perspective of imperviousness to fire, molecule sheets are burnable structure materials. Uncoated particleboard can meet the class necessities of D-s2 and d2, and covered (smooth-surfaced) Particleboard can meet the prerequisites of C-s2 and d1.

MDF comprises slender boards produced using wood fiber, tar, and wax. With regards to designed wood, MDF is frequently viewed as a level over the pressed wood. It is denser, more grounded, and more sturdy. Therefore, it has nearly the same number of utilizations as strong wood.

While neither one of the versions does well around water, HDF is more water-safe than MDF, and its thickness does likewise make it more grounded. Utilizing a facade on MDF can likewise make the fantasy of strong wood. While it’s not as solid as HDF, it’s as yet an entirely strong material that won’t extend or contract with warmth and moistness.

Pressed wood and OSB (arranged strand board) underlying boards are genuine wood, a characteristic protector, and hence give great insurance against heat misfortune and buildup. Enormous board size additionally limits the number of joints that can “release” heat, airborne clamor, or blazes.

Maple is affordable and super strong. It can get hammered and look incredible for quite a long time. Since it takes dull colors well, maple is frequently finished to impersonate a pricier wood, similar to cherry or mahogany (which is a dubious pick itself in view of deforestation in the districts where it’s collected).

Oak wood is incredibly Strength, weighty, and tough. It is an alluring light tone with a noticeable grain and is impervious to contagious assault, because of its thick constitution and long-living nature, which should prepare the tree for its long lifetime.

Alder has been portrayed as ‘satisfying’ in appearance, with grain that is regularly straight and stifled. In spite of the fact that the shading has frequently been depicted as sensitive, the wood is with no extraordinary figure. Hard, solid, flexible wood is bendable and stuns safe.

Hickory wood is supposed to be exceptionally hard, solid, thick, and stun safe, bragging a blend of strength and durability that isn’t found in other business woods. Since it is additionally fairly flexible, it says the wooden squanderers twist as opposed to fragmenting when struck.

Birch is a local hardwood that comes from the class Betula. There are over twelve types of birch trees local to North America, however the most well-known are white birch, yellow birch, and dark birch. Yellow birch and white birch are the two most normally found in carpentry.

Walnut is a solid, hard, and durable wood that cuts well and holds a decent shape for various years. This settles on it is a great decision for elaborate furniture that requires complex carpentry, for example, a mantelpiece or headboard. Walnut furniture can without much of a stretch endure forever with appropriate consideration and upkeep.

Pecan is the most strong wood species developed locally with a Janka rating around 1820. So while there may be a few drawbacks of hickory flooring, strength isn’t among them. Pecan is a delightful and interesting wood species that sports different tones and a huge load of grain character.

Sapele is a little stronger than red oak. The bending strength (MOR) is 15,300 psi, the elasticity (MOE) is 1.82 million psi, and the hardness is 1510 pounds.

It has a lovely pine fragrance and is marginally resinous. Ponderosa Pine is by and large perceived as the most flexible wood found in bounty in North America. Its uses range all through each period of light development. Poor quality timber is utilized for boxes, cartons and wood bundling.

Mahogany is more earnestly than different woods like oak, pine, and so forth Indeed, it is 70% more steady and harder than different assortments of woods. Its properties of hardness and strength having no scores or pockets make it water-resistant and without scratch as well. The greatest bit of leeway of mahogany hardwood floors is their appearance.

Rot Resistance: Butternut wood Has excellent decay resistance, and is rated as durable to very durable. Butternut wood is also reported to be resistant to termites and other insects.

With Ash commonplace straight grain and beige-to-light-brown tint, ash wood is an extremely appealing alternative for fine furnishings. It’s perhaps the most strong assortments and has a broad history in American furniture making. It is solid, lightweight, tastefully satisfying, and retains wood finishes well.

Starting from Asia or Africa, padauk wood can be acquired from a wide assortment of Pterocarpus species. Regularly alluded to as narra or mukwa, padauk wood is a significant asset because of its toughness, strength, and steadiness when being worked.

One of the characterizing qualities of Purpleheart wood is the strength, thickness, and toughness of its timber structure. Purpleheart is so solid, it can undoubtedly be considered as one of the most grounded and densest trees accessible available.

With teak remaining one of the world’s most valuable timbers, interest in growing and investing in the species will remain high. Teak is exceptionally resistant in an outdoor environment. After three years, the wood will have developed fire-resistant properties, allowing the timber natural fire protection.

What Other Ideas

Are You Interested In For Your Home & kitchen?

Enter a name below to see if we have information available:

Check out these other awesome varieties you can learn about:

Yellow Color Combinations: The Best Colors to Pair with Yellow for a Stunning Look

Will You Miss 2024’s Concrete Floor Innovations? Upgrade Today!

Will One Room Challenge 2024 Unfold a Remarkable Transformation?

Share your experience or ask a question about this Post in the comments below